+86-18058825678

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Our Product

- About Didtek

- Solutions

- Exhibition Show

- Support

- News

Views: 0 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

Solenoid valves are critical components in various industrial and domestic applications, enabling precise control over the flow of liquids and gases. This comprehensive guide explores the different types of solenoid valves, their mechanisms, and their specific applications. By understanding the various designs, such as normally closed, normally open, and bi-stable valves, you can make informed decisions for your fluid control needs. Whether you're working in manufacturing, HVAC, or home automation, this guide will help you navigate the essential features and benefits of solenoid valves to optimize system performance.

A solenoid valve mainly consists of a coil, plunger, spring, seal, and valve body. The coil is a wire wrapped around a core that becomes an electromagnet when energized. The plunger, made of iron or steel, sits inside the coil and moves up or down based on the magnetic force. A spring pushes the plunger back to its original position when the coil is off. The seal blocks or allows fluid flow through the valve’s orifice, which is part of the valve body. These parts work together to control fluid flow precisely and quickly.

Electricity powers the coil, creating a magnetic field that pulls the plunger. When the coil is energized, the magnetic force overcomes the spring’s push. This movement either opens or closes the valve, depending on its design. The coil’s voltage and current must match the system’s power supply for proper operation. When power cuts off, the spring returns the plunger to its resting position, stopping or allowing flow. This electrical control allows solenoid valves to operate remotely and automatically, making them ideal for many industrial uses.

The valve’s open or close state depends on the plunger’s position. In normally closed valves, the plunger seals the orifice when de-energized, blocking flow. When energized, the plunger lifts, opening the orifice and allowing fluid to pass. Normally open valves work oppositely; the plunger rests off the orifice to allow flow when de-energized and moves to close it when energized. The quick movement of the plunger ensures fast response times, which is crucial in applications requiring precise fluid control.

Matching the coil voltage to your system’s power supply ensures reliable solenoid valve operation and prevents coil damage.

Solenoid valves come in several types, each designed to suit specific applications and operational needs. Understanding these types helps in selecting the right valve for your system.

● Normally Closed (NC) ValvesThese valves remain closed when not energized. The plunger seals the orifice, blocking fluid flow. When the coil is energized, the magnetic field pulls the plunger up, opening the valve and allowing flow. NC valves are energy-efficient for applications requiring the valve to stay closed most of the time. They are also safer for systems needing automatic shut-off during power loss, such as gas appliances.

● Normally Open (NO) ValvesNO valves stay open when de-energized, allowing fluid to flow freely. Energizing the coil pulls the plunger down to seal the orifice, stopping flow. This design suits applications where fluid must flow continuously unless interrupted, like in cooling systems or overpressure prevention.

Bi-stable, or latching, solenoid valves hold their last position without continuous power. They use permanent magnets to keep the plunger in place after a brief electrical pulse moves it. This reduces power consumption significantly and is ideal for applications with infrequent switching, such as irrigation systems or safety locks.

● Direct Acting ValvesThese valves open or close solely by the solenoid’s magnetic force, without relying on fluid pressure. They work well for low flow rates and pressures and offer fast response times. Their simple design suits compact spaces and precise control needs.

● Indirect Acting (Pilot Operated) ValvesIndirect valves rely on pressure differences to function. The solenoid controls a small pilot orifice that, when opened, changes pressure above a diaphragm or piston, causing the main valve to open. These valves handle higher flow rates and pressures but need a minimum pressure differential (around 0.5 bar) to operate. They are common in water treatment and industrial fluid control.

● Semi-Direct Acting ValvesThese combine direct and indirect principles. The solenoid directly lifts the plunger, which assists in opening the valve by releasing pressure above a diaphragm. This design allows operation at zero pressure differential and supports higher flow rates than direct acting valves. Semi-direct valves offer a balance of power efficiency and performance.

Normally closed valves are preferred for safety-critical systems, while bi-stable valves save energy in low-switching-frequency applications. Choose valve type based on your system’s power availability, safety needs, and flow control requirements.

Solenoid valves control the flow of liquids or gases by opening, closing, or redirecting the flow path. Their specific purpose depends on the number of ports and how these ports connect during operation. The circuit function describes this behavior. Let's explore the most common types: 2-way, 3-way, 4-way, and 5-way solenoid valves.

2-way solenoid valves have two ports: an inlet and an outlet. They simply allow or block flow between these ports. The flow direction matters for correct operation and is usually marked by an arrow on the valve body. When energized, the valve either opens or closes to start or stop the flow. These valves are ideal for on/off control in simple systems like water supply lines or gas shutoff.

Key Features:

● Two ports: inlet and outlet

● Controls flow start or stop

● Common in simple fluid control systems

3-way solenoid valves have three ports, each serving a unique function. Typically, these ports are:

● P (Pressure or Inlet Port): Where fluid enters.

● A (Actuator or Outlet Port): Connects to the device or actuator.

● E or R (Exhaust or Return Port): Allows fluid to exit or vent.

Depending on energizing the coil, the valve switches flow paths between these ports. For example, in a normally closed 3-way valve, the inlet (P) is blocked when de-energized, and the outlet (A) connects to exhaust (E) to release pressure. Energizing the coil opens flow from P to A, closing the exhaust.

3-way valves are widely used to control single-acting pneumatic cylinders, allowing pressurizing and exhausting through the valve.

Key Features:

● Three ports for versatile flow control

● Switches flow between inlet, outlet, and exhaust

● Common in pneumatic and actuator control

4-way and 5-way valves are more complex and mainly found in pneumatic and hydraulic systems controlling double-acting actuators.

● 4-Way Valves: Usually have four ports — two inlets and two outlets. They switch flow direction to extend or retract an actuator. When energized or de-energized, the valve shifts positions, changing which ports connect. This allows precise control over actuator movement.

● 5-Way Valves: Add an extra exhaust port to the 4-way design. The additional port helps vent air or fluid quickly, improving response times and efficiency. These valves are ideal for applications requiring rapid or precise motion control like robotics or packaging machines.

Key Features:

● 4-way: Controls direction with four ports

● 5-way: Adds exhaust port for faster venting

● Used in double-acting cylinders and complex systems

Always verify the flow direction markings on solenoid valves to ensure correct installation and optimal performance in your system.

The housing material of a solenoid valve plays a crucial role in its durability and compatibility with the fluid it controls. Common materials include:

● Brass: Known for good corrosion resistance in neutral media like water. It is cost-effective and widely used.

● Stainless Steel: Offers excellent resistance to chemicals, high temperatures, and pressure. Ideal for harsh environments.

● PVC (Polyvinyl Chloride): Lightweight and corrosion-resistant, suitable for aggressive chemicals and cost-sensitive applications.

● Aluminum: Combines light weight and strength, with good thermal properties; often used in industrial settings.

● Cast Iron: Provides strength and wear resistance, with added vibration damping, making it suitable for heavy-duty applications.

Selecting the right housing material depends on the fluid type, temperature, pressure, and environmental conditions. For example, stainless steel is preferred in chemical processing, while brass suits water systems.

Seals prevent leaks and ensure tight closure. Their material must match the media's chemical nature and operating temperature. Common sealing materials include:

● NBR (Nitrile Butadiene Rubber): Resistant to oils and fuels, ideal for petroleum-based fluids.

● EPDM (Ethylene Propylene Diene Monomer): Excellent against weathering, ozone, and steam; great for hot water and outdoor use.

● FKM (Viton): High resistance to chemicals and heat, suitable for harsh chemical environments.

● PTFE (Teflon): Exceptional chemical inertness and wide temperature range, perfect for aggressive fluids and extreme conditions.

Choosing the right seal extends valve life and prevents contamination or damage. For instance, EPDM is not suitable for petroleum oils, so NBR would be better in such cases.

Media-separated solenoid valves isolate the fluid from the valve’s moving parts, protecting sensitive components from aggressive or contaminated media. This design often uses a diaphragm or bellows to separate the fluid chamber from the actuator mechanism.

Advantages include:

● Protection against corrosion and wear.

● Ability to handle slightly contaminated or aggressive fluids.

● Longer service life in challenging environments.

These valves are common in chemical processing, pharmaceuticals, and food industries where purity and durability are critical.

Always verify both housing and sealing materials against your fluid’s chemical properties and operating conditions to ensure optimal solenoid valve performance and longevity.

Many solenoid valves incorporate electric power reduction features to improve energy efficiency. Initially, the valve receives a full rated voltage to actuate quickly. Once the valve reaches its operating position, the voltage drops to a lower holding level, just enough to keep the valve open or closed. This reduces power consumption and heat generation, extending the valve coil’s life and lowering operating costs. This feature is especially useful in valves that remain energized for long periods.

Manual override allows operators to open or close the valve manually without electrical power. This is valuable during commissioning, maintenance, or emergencies when electrical control is unavailable. Some valves include a locking mechanism to prevent accidental manual operation.

Latching, or bi-stable, solenoid valves use a short electrical pulse to switch positions. After that, a permanent magnet holds the plunger in place without continuous power. This reduces energy use and heat buildup, making it ideal for applications with infrequent switching, such as irrigation systems or safety locks.

Solenoid valves often require specific approvals to meet industry standards and safety regulations. Common certifications include:

● UL/UR: Certifies electrical safety and performance.

● Drinking Water Approvals: Such as NSF, WRAS, KTW, ACS, and Watermark, ensuring materials are safe for potable water.

● FDA: For food and pharmaceutical applications.

● ATEX: Certification for explosion protection in hazardous environments.

● CE: Confirms compliance with European safety, health, and environmental requirements.

● DVGW: For gas valves in Europe.

● IP Ratings: Indicate protection against dust and water ingress.

Choosing a valve with the right certifications ensures compliance and reliability in your application.

Opt for solenoid valves featuring power reduction and manual override to enhance energy efficiency and operational flexibility, especially in critical or remote applications.

Solenoid valves are versatile components found in many industries and everyday devices. They control the flow of liquids or gases automatically, making processes safer, faster, and more efficient. Let’s explore some key application areas.

In industrial settings, solenoid valves manage fluids in manufacturing, processing, and automation. They control water, air, oil, and gases in factories to regulate machines and systems. For example:

● Water Treatment Plants: They open and close valves to control water flow and chemical dosing.

● Food and Beverage Industry: Used for precise fluid control in processing and packaging.

● Chemical Processing: Handle aggressive fluids safely by using compatible materials.

● Automotive Manufacturing: Control pneumatic tools and robotic arms for assembly lines.

Commercial buildings also use solenoid valves for heating, ventilation, and air conditioning (HVAC) systems. They regulate refrigerants and water flow to maintain temperature and comfort.

Solenoid valves play a crucial role in pneumatic and hydraulic systems by controlling air or fluid pressure to operate cylinders and actuators.

● Pneumatics: Valves direct compressed air to power tools, machinery, or automation systems. For instance, 3-way or 5-way solenoid valves control single or double-acting cylinders.

● Hydraulics: They regulate oil flow in heavy equipment like excavators, presses, and lifts. 4-way valves control the movement direction of hydraulic cylinders.

These valves ensure quick, precise movements and improve safety by allowing remote control and automatic shut-off.

Solenoid valves are also common in household appliances and systems, improving convenience and safety.

● Dishwashers and Washing Machines: Control water intake and drainage cycles.

● Irrigation Systems: Automate garden watering based on timers or sensors.

● Refrigeration: Manage refrigerant flow for cooling and defrost cycles.

● Water Tanks: Regulate filling and draining to prevent overflow.

● Automatic Door Locks: Use solenoid valves as part of locking mechanisms.

These applications benefit from the valves’ fast response and reliability.

When choosing solenoid valves for specific applications, consider the fluid type, operating pressure, and required response time to ensure optimal performance and longevity.

Choosing the right solenoid valve starts with knowing the fluid type it will control. Different fluids—water, oil, gas, chemicals—have unique properties that affect valve performance. For example, corrosive fluids require valves made from materials resistant to chemical attack, such as stainless steel or special seals like PTFE (Teflon). Water systems often use brass valves with EPDM seals, while petroleum-based fluids suit valves with NBR seals.

Compatibility is key to preventing leaks, corrosion, and valve failure. Always check the chemical compatibility of both valve housing and seal materials against the fluid. Media-separated valves, which isolate the fluid from moving parts, are excellent for aggressive or contaminated fluids.

Next, consider the system’s pressure and temperature ranges. Solenoid valves have maximum and minimum pressure ratings. Exceeding these can damage the valve or cause malfunction. For low-pressure systems, direct-acting valves work well since they operate without pressure differential. Pilot-operated valves require a minimum pressure difference (typically around 0.5 bar) to function properly and handle higher flows.

Temperature affects valve materials and seal performance. High temperatures may degrade seals like EPDM, requiring FKM or PTFE for durability. Low temperatures can stiffen seals, causing leaks or slow response. Always verify the valve’s rated temperature range fits your application.

Response time—the speed at which a valve opens or closes—is critical in many applications. Direct-acting valves usually respond in milliseconds and suit fast control needs. Indirect or semi-direct acting valves may respond slower but handle higher flow rates. Consider your system’s timing demands carefully.

Finally, check for necessary approvals and certifications. For example, valves handling drinking water should have NSF or WRAS certification. Industrial applications may require UL, CE, or ATEX approvals. These certifications ensure safety, reliability, and regulatory compliance.

Always match valve materials and seals to your fluid’s chemical properties and operating conditions to maximize performance and lifespan.

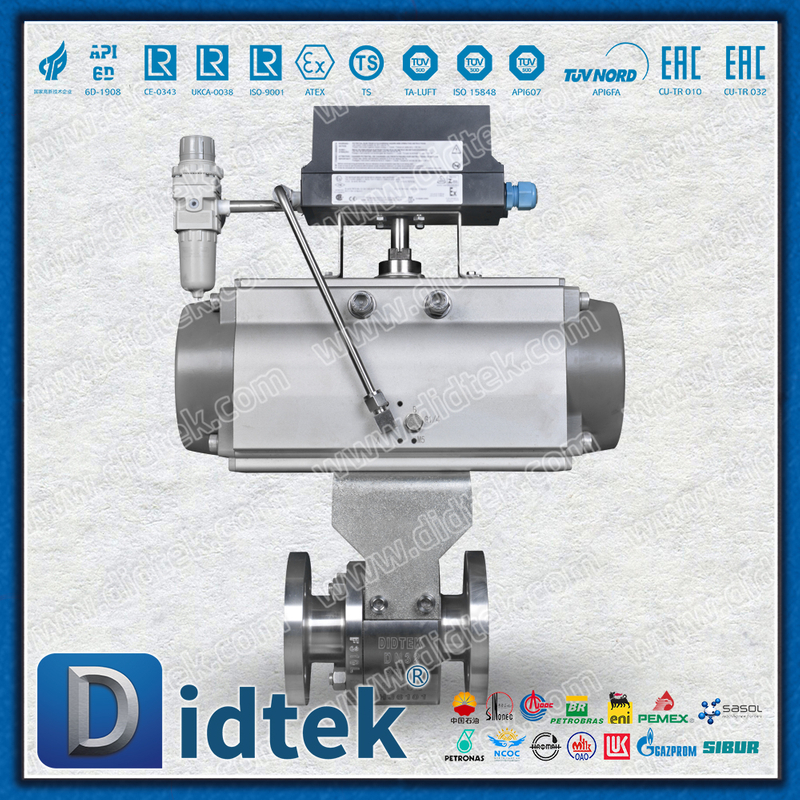

Solenoid valves are essential for controlling fluid flow in various applications, such as industrial, pneumatic, and domestic systems. Understanding the types, including normally closed, normally open, and bi-stable valves, is crucial for optimal performance. Future trends focus on energy efficiency and advanced materials. Selecting the right valve involves considering fluid compatibility, pressure, and temperature requirements. Company Profile - Didtek Valve Group offers high-quality solenoid valves that enhance system efficiency and reliability, ensuring long-term value and performance for diverse industrial needs.

A: A Solenoid Valve is an electromechanically operated valve used to control the flow of liquids or gases in various applications.

A: A Solenoid Valve works by using an electric current to generate a magnetic field, which moves a plunger to open or close the valve.

A: Solenoid Valves offer precise, fast response times and remote operation, making them ideal for automated fluid control systems.

A: Normally Closed Solenoid Valves are energy-efficient and safer for systems requiring automatic shut-off during power loss.

A: Consider fluid type, pressure, temperature, response time, and necessary certifications to select the appropriate Solenoid Valve.