+86-18058825678

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Industrial Valve

- About Didtek

- Solutions

- Exhibition Show

- Support

- News

Views: 0 Author: Site Editor Publish Time: 2025-08-13 Origin: Site

The wafer check valve vs flanged check valve debate is about size, weight, and how each valve fits in a pipeline. Flanged check valves are strong and heavy. They have flanged ends. This makes them good for high-pressure jobs. Wafer check valve vs flanged check valve shows wafer valves save space. They also install faster. They fit tightly between flanges. Picking the right valve in the wafer check valve vs flanged check valve comparison means better performance. It also means less trouble for every use.

Wafer check valves are small and light. They save space. This makes them good for tight pipelines. They are also quick to install.

Flanged check valves are heavy and strong. They work best in high-pressure systems. These valves give a safe, leak-proof connection.

Wafer valves let fluids flow better. They have low pressure drop. They close fast to stop water hammer. This helps save energy.

Flanged valves work well in tough places. They handle dirty fluids and high heat. They last longer in hard industrial jobs.

Picking the right valve depends on space and pressure. You also need to think about fluid type and maintenance. This keeps things safe and working well.

Wafer check valves are easy to take out and fix. You do not need to cut pipes. This saves time and repair money.

Flanged check valves need more space. They must be put in carefully. But they are more stable and last longer.

Checking valves often and picking the right size stops problems. This helps the system last longer and cuts repair costs.

Wafer check valves are small and easy to fit. They go between two pipeline flanges. This saves space and makes the piping lighter. Many engineers pick wafer check valves when there is not much room. They also use them to keep the system light. The table below shows how size and weight are different:

Valve Type | Size Range (DN) | Weight Comparison |

|---|---|---|

Wafer Check Valves | 25 to 1000 | Significantly lighter than flanged check valves |

Flanged Check Valves | N/A | Heavier and bulkier |

A wafer check valve fits in tight places. Flanged check valves cannot always do this. This makes wafer check valves good for fixing or updating old systems.

Flanged check valves are much bigger and heavier. The flanges add more material and weight. These valves need more space in the pipeline. Their strong build gives them strength and helps them last longer. But installers need more room and support for them. In places with high pressure or lots of shaking, flanged check valves stay steady and last a long time.

Wafer check valves use a sandwich-style connection. The valve goes between two pipeline flanges. Bolts hold it in place. This makes installation fast and simple. You do not need to line it up perfectly. This saves time and work. Wafer check valves are good for small spaces. They are also easy to take out for repairs.

Flanged check valves have flanges on both ends. Installers bolt these flanges to the pipeline. This job needs careful lining up and skill. The connection is strong and does not shake loose. It also holds up well under pressure. Flanged check valves are best for tough jobs where safety is important.

Here is a comparison of connection types:

Aspect | Wafer Check Valves | Flanged Check Valves |

|---|---|---|

Connection Design | Sandwiched between pipeline flanges | Integrated flanges bolted to pipeline flanges |

Installation Complexity | Quick, easy, less alignment needed | More complex, precise alignment required |

Stability and Suitability | Good for compact spaces, less stable under stress | Superior stability, best for high pressure/vibration |

Maintenance Considerations | Easy to remove and replace | Harder to install or replace, but more durable |

Modern wafer check valves have a special body shape. This gives the disc room to swing open all the way. The disc moves easily, so fluid flows with little resistance. Some wafer check valves have springs. The springs help the disc close fast. This stops backflow and water hammer. Spring-loaded wafer check valves also seal well at low pressure. This makes them more reliable.

Flanged check valves often use a swing disc. The disc opens when fluid moves forward. It closes when the flow goes backward. The bigger body of flanged check valves can slow the disc. This happens more in older designs.

Wafer check valves let fluid flow better. Their small shape and moving disc lower pressure drop. This means the system uses less energy. Wafer check valves can go in pipes that are vertical or horizontal. This makes them flexible for many uses.

Flanged check valves are strong and steady. But they can slow down the flow more. Their big body and heavy disc can make the system lose pressure. Still, flanged check valves work well in tough places.

Tip: If you need to save space and energy, wafer check valves are a good choice. For pipelines with high pressure or lots of shaking, flanged check valves are best for strength and long life.

International standards like API 594 and ASME B16.34 are important for both wafer check valves and flanged check valves. These rules cover design, materials, pressure, and testing. API 594 makes sure wafer check valves are small and work well in tight spaces. ASME B16.34 sets rules for pressure and materials in hard conditions.

New technology has made both valves better. Wafer check valves now have molded bodies and spring discs. They also use materials that do not rust. These changes make them work better and last longer. Flanged check valves also use better materials and new ways to build them. This makes them stronger and less expensive.

Picking a wafer check valve or a flanged check valve depends on what your system needs. Think about space, pressure, flow, and repairs before you choose.

Putting in a wafer check valve is quick and easy. You do not need much time or effort. Here are the steps:

Look for the arrow on the valve. Make sure it points the same way as the fluid.

Put the wafer check valve between two pipeline flanges. If the pipe is sideways, keep the hinge pin straight up and down.

Use flanges that fit well and clean them first. Pick a gasket that works with the fluid and heat.

Put in the bolts and tighten them in a crisscross way. This stops leaks and spreads pressure evenly.

When you start the system, check the bolts again. Tighten them more if you need to.

Tip: Do not put wafer check valves near elbows or pumps. This helps the valve work better and last longer.

Flanged check valves need more space and careful lining up. Here are the steps:

Check which way the fluid goes and put the valve in right.

Line up the flanged ends with the pipeline flanges. You must be careful here.

Clean the flanges and pick the best gasket for the job.

Put grease on the bolts, put them in, and tighten them in a cross pattern. This makes a strong seal.

After using the system, check the bolts and tighten them again if needed.

Flanged check valves hold tight, so they are good for high-pressure systems.

Wafer check valves are small and save space. Their face-to-face size is much shorter than flanged check valves. Sometimes it is only one-fourth or one-eighth as long. This makes them great for tight spots or fixing crowded pipes.

Wafer check valves do not need much extra room to install. They fit right between flanges and need fewer extra parts. Flanged check valves are bigger and need more space for the valve and tools. If you do not have much room, wafer check valves are better.

Valve Type | Face-to-Face Length | Clearance Needed |

|---|---|---|

Wafer Check Valve | Short | Minimal |

Flanged Check Valve | Long | Significant |

Wafer check valves are easy to take out and check. This saves time and money on repairs. Flanged check valves are heavier and harder to reach. But they are strong and last longer in tough places.

Check both types of valves often to keep them working well. Look at wafer check valves at least once a year. In rough places, check them every six months or even every three months. Flanged check valves may need a big fix every two to five years. This means taking them apart, cleaning, and putting in new parts. Doing these checks helps the valves work well and stops big problems.

Note: Doing the right steps for putting in and checking valves helps them last longer. Picking the best valve and following good rules means fewer problems and less money spent.

Wafer check valves work well in medium pressure and temperature. Most can handle up to 235 psi. They work in temperatures from -10 °C to 180 °C. Stainless steel wafer swing check valves also handle 235 psi. They work up to 120 °C. Some chemical models work at 10 bar and up to 180 °C. These ratings make wafer check valves good for water systems. They are also used in HVAC and chemical jobs. They work best when conditions do not change much.

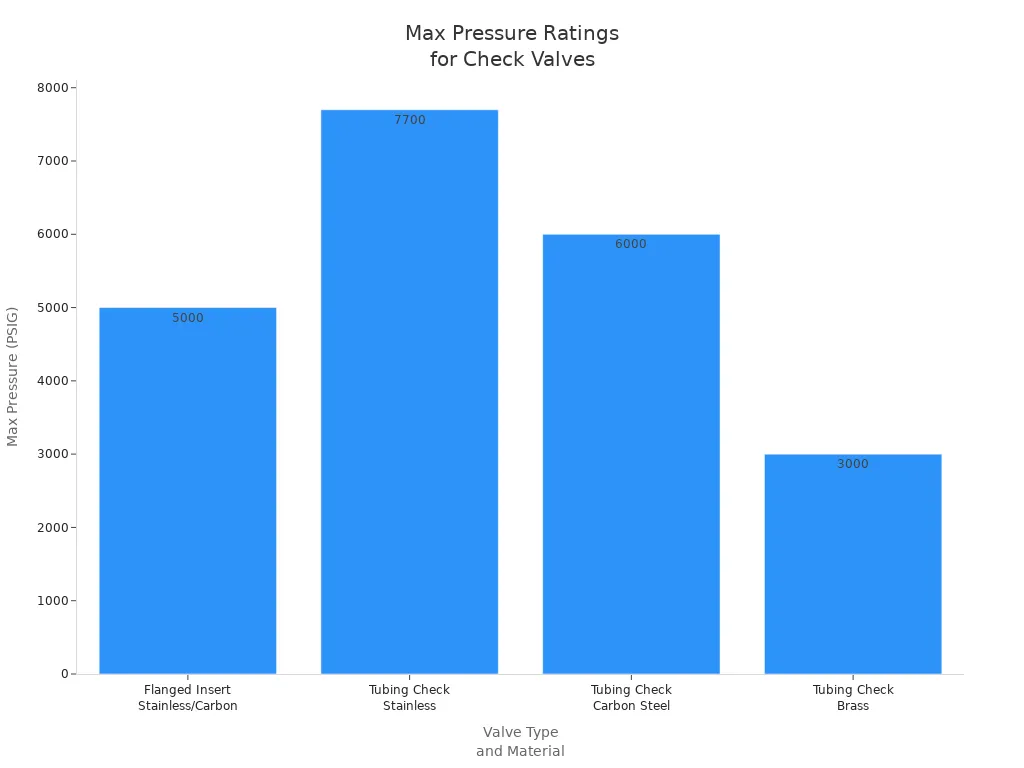

Flanged check valves are used for tough jobs. They can handle much higher pressure and heat than wafer check valves. Some flanged insert valves use stainless steel or carbon steel. They can take up to 5000 PSIG (about 345 bar) at 100 °F. Tubing check valves can go up to 7700 PSIG (530 bar) for stainless steel. Carbon steel tubing check valves reach 6000 PSIG (414 bar). Brass models can handle up to 3000 PSIG (207 bar). The temperature limit depends on the seat and spring. Always check with the maker if you need more than 100 °F.

Valve Type | Material | Max Pressure (PSIG/bar) | Max Temperature (°F/°C) |

|---|---|---|---|

Flanged Insert Valves | Stainless Steel, Carbon Steel | Up to 5000 PSIG (approx. 345 bar) at 100 °F | Ask the factory for >100 °F |

Tubing Check Valves | Stainless Steel | Up to 7700 PSIG (approx. 530 bar) at 100 °F | Depends on seat/spring materials |

Tubing Check Valves | Carbon Steel | Up to 6000 PSIG (approx. 414 bar) at 100 °F | Depends on seat/spring materials |

Tubing Check Valves | Brass | Up to 3000 PSIG (approx. 207 bar) at 100 °F | Depends on seat/spring materials |

Flanged check valves are very strong. They work well in high-pressure pipelines and big factories. Their tough build keeps things safe even when conditions are hard.

Water hammer can break pipes and machines. Wafer check valves help stop water hammer. They use springs and double-eccentric discs. These parts close the valve fast when flow goes backward. This stops backflow and sudden pressure jumps. Dual plate wafer check valves use spring discs. They close without slamming and stop water hammer. Their light weight and quick closing protect other equipment.

Flanged check valves also help with water hammer. Swing check valves close before the flow goes backward. This lowers slam and water hammer. Some have angled seats and spring discs. These help the valve close quietly and smoothly. These features help flanged check valves work well in high-pressure places.

Wafer check valves lower water hammer pressure a lot. They can cut it to half or even one-fifth of what flange type swing check valves have. Their non-slam design and tight seal make them great for high-pressure jobs like fire pumps. Flanged check valves are heavier and more old-fashioned. But their strong build helps keep the system safe.

Picking the right valve to stop water hammer keeps your system safe. It also saves money on repairs.

Wafer check valves are slim and light. This means fluid moves through them easily. They have very low pressure drop. Their opening pressure is very low. Swing check valves, especially flanged ones, slow the flow more. Their swinging disc and big body cause higher pressure drop.

Wafer check valves close fast and lower water hammer pressure. They let fluid flow easily and save energy. Flanged check valves have higher pressure drop. This can make the system less efficient. Wafer check valves save more energy and help fluid move better.

Wafer check valves let fluid flow easily.

Swing check valves slow the flow more.

Wafer check valves need very little pressure to open.

Swing check valves usually have higher pressure drop than wafer check valves.

If you want your system to work better and lose less pressure, wafer check valves are a smart pick.

Engineers want valves that last a long time. Wafer check valves and flanged check valves are both strong, but in different ways. Wafer check valves are small and have fewer moving parts. This makes them less likely to break. Many wafer check valves use materials that do not rust, like stainless steel or special metals. These materials help stop rust and chemical damage. In clean water or gentle chemicals, wafer check valves can work for years without problems.

Flanged check valves are known for being tough. They are made with thick walls and strong flanges. This helps them handle high pressure and lots of shaking. Flanged check valves often have extra-strong seats and discs. These parts protect the valve from wearing out, even in rough places. In oil plants or power stations, flanged check valves keep working when other valves might stop.

Tip: If your system shakes a lot or has sudden pressure changes, flanged check valves are safer. Their strong build means they break less and need fewer repairs.

How long a check valve lasts depends on where it is used, what flows through it, and how often it opens and closes. Wafer check valves usually last a long time in low or medium pressure systems. Their simple design means fewer things can wear out. Many wafer check valves work for five to ten years in water or HVAC systems. Checking and cleaning them often can make them last even longer.

Flanged check valves often last longer than wafer check valves in hard jobs. Their strong bodies and tough parts stop damage from rough fluids or high heat. Some flanged check valves work for many years, even decades, if you take care of them. You can change the inside parts, like seats and discs, to fix the valve without taking it out of the pipe.

Valve Type | Typical Service Life | Best Use Case |

|---|---|---|

Wafer Check Valve | 5-10 years | Clean water, HVAC, mild chemicals |

Flanged Check Valve | 10-20+ years | Oil & gas, power plants, heavy duty |

A good valve keeps the system safe and saves money on repairs. Picking the right valve helps everything work better and keeps things running. Facility managers should always choose the valve that fits the job best.

Wafer check valves are important in water systems. They are light and small, so they fit in tight spots. Many engineers use them to stop water from flowing backward in pumping stations. They also help protect machines in water treatment plants. Wafer check valves keep water clean and stop bad stuff from moving back through the pipes.

Water pumping systems use wafer check valves to block reverse flow.

Industrial water plants use these valves to keep equipment safe.

Building water systems like that these valves save space.

Wafer check valves work well in water systems. They are a good pick for new or old setups.

Some systems do not have much room. Wafer check valves are thin and small, so they fit well. They go between flanges and do not need much support. They are quick to put in. Many places use them in HVAC, power plants, and pipes where space is tight.

HVAC systems use wafer check valves to control flow in small spaces.

Power plants put these valves where every inch matters.

Ships and offshore places use wafer check valves because they are light and small.

These valves stop water hammer and lower pressure drop. This makes them great for places with little space.

Flanged check valves are best for high-pressure pipes. They are strong and can handle very high pressure. Oil and gas pipes use these valves to stop dangerous backflow. This keeps leaks, mixing, and explosions from happening. Flanged check valves protect pumps and compressors by stopping reverse flow.

These valves also keep different fluids from mixing. Their tight seal makes them needed in tough jobs.

Factories need valves that can handle rough work. Flanged check valves are good for this. They work on their own to control flow and stop backflow. Factories and plants use them in both sideways and up-and-down pipes. Their strong build helps them last a long time, even with lots of use and pressure changes.

Flanged check valves are very reliable in factories. They are a top pick for important jobs.

Water treatment plants use wafer check valves to stop backflow and protect machines. These valves work by themselves and do not need much fixing. Flanged check valves are also used in water treatment, mostly where pressure is high or the job is tough.

Oil and gas companies use both wafer check valves and flanged check valves. Wafer check valves save space in pipes and machines. Flanged check valves do the hardest jobs, like handling high pressure and keeping costly machines safe. Both types meet strict rules to keep people and equipment safe.

Picking the right valve for each job keeps systems safe, works well, and saves money over time.

A wafer check valve has many good points for new piping. Engineers pick this valve because it saves space. It fits easily between pipe flanges. The valve is light, so it is easy to put in. You do not need heavy supports. The inside is smooth, so fluid moves with little pressure loss. This helps the system work better. The valve shuts fast to stop backflow. This keeps pumps safe from harm. It works by itself, so no one needs to open or close it. Many places use this valve, like water plants, oil and gas, chemical plants, and HVAC. The strong build meets safety rules and helps users feel safe.

The design saves space in small areas.

It is light and simple to move.

It lets fluid flow with little pressure loss.

The disc closes fast to stop water hammer.

It works on its own, no manual work needed.

It works with many fluids and temperatures.

It saves money and cuts repair time.

Tip: A wafer check valve is great for small spaces and smooth flow.

Even with many good points, this valve has some weak spots. It does not work well in very high pressure or heat. If fluid moves too fast, the valve might not work right. Thick or dirty fluids can make it hard for the valve to close. People must check the pressure rating and pick the right material for the fluid. Checking and cleaning the valve often is needed to keep it working.

Not good for very high pressure or heat.

Can have trouble with fast-moving fluid.

Does not work well with thick or dirty fluids.

Needs careful picking for each job.

Note: Always check the valve’s pressure and material before you use it in a new system.

A flanged check valve is strong and very reliable. It can handle high pressure and heat with no problem. Its tough build keeps it steady, even if the system shakes. The flanged ends make a tight seal to stop leaks. This keeps the system safe. Many factories and big plants use this valve for hard jobs. It lasts a long time and you can fix it by changing inside parts.

Handles high pressure and heat well.

Stays strong in rough conditions.

Tight seal stops leaks.

Lasts long and parts can be replaced.

Used in factories and risky places.

This valve has some downsides too. It is big and heavy, so putting it in is harder and costs more. It needs more room in the pipe and often needs extra support. It costs more and takes longer to install. Taking it out or swapping it is harder than with lighter valves.

Big and heavy, needs more space.

Costs more to put in and fix.

Harder to take out or swap.

Not good for small or light systems.

Tip: Pick a flanged check valve when you need safety and strength, especially for tough jobs.

Picking the right check valve starts with knowing the job. Each system needs something different. Some systems need to handle high pressure. Others need to fit in small spaces. The fluid type, how fast it moves, and pipe direction all matter. Wafer check valves fit best where space is tight. They work well in water, HVAC, and chemical systems. Flanged check valves are good for high-pressure jobs and big pipes. They give strong, leak-proof connections.

Key things to think about:

Make sure the valve size and pressure rating match the system.

Choose materials that do not rust and fit the fluid.

Check if the valve works in sideways or up-and-down pipes.

Think about how easy it is to reach the valve for repairs.

See how the valve affects flow and sealing.

Selection Criteria | Wafer Check Valves | Flanged Check Valves |

|---|---|---|

Footprint | Smaller, compact design | Larger due to flanged connections |

Connection Method | Between flanges, no bolts needed | Bolted with gaskets |

Installation Space | Great for limited space | Needs more space for bolting |

Ease of Installation | Quick and simple | More labor and alignment needed |

Maintenance | Fewer parts, may be simpler | Gasket and bolts need checking |

Application Suitability | Space-saving jobs | Strong, leak-tight jobs |

Material Compatibility | Matches pipe flange materials | Matches pipe flange materials |

Budget is important for every project. The first price is not the only cost. Wafer check valves cost less to buy and put in. They are light, so workers finish faster. Flanged check valves cost more at first. They need more space and time to install. Over time, you pay for repairs, downtime, and new valves. Sometimes, a more expensive valve saves money because it lasts longer and needs less fixing.

Budget Factor | Wafer Check Valves | Flanged (Swing) Check Valves |

|---|---|---|

Initial Purchase | Lower cost, lightweight | Higher cost, heavier |

Installation | Quick, low labor | More labor, higher cost |

Maintenance | Less frequent, lower cost | More frequent, higher cost |

Lifetime Cost | Lower total cost for most jobs | Higher, but justified for tough jobs |

Maintenance keeps everything working well. Wafer check valves have fewer parts, but their small size can make fixing hard. Flanged check valves are bigger, so workers can reach inside more easily. Both types need regular checks for wear, leaks, and dirt. Cleaning and changing seals helps stop problems. Keeping good records of checks and repairs helps find issues early.

Maintenance checklist:

Look for wear, rust, and dirt.

Clean to stop buildup.

Change seals to stop leaks.

Test the valve when the system is off.

Write down all work done.

Pick this valve for small spaces or when weight matters.

Use it in water, HVAC, or chemical systems with medium pressure.

Choose it when you want fast installation and low cost.

Make sure the fluid is clean and flows smoothly.

Check if you can reach the valve for repairs.

Pick this valve for high-pressure or fast-flow jobs.

Use it in oil, gas, or big factories.

Choose it when you need a strong, leak-proof connection.

Use it for dirty fluids or lots of shaking.

Plan for more space and longer installation time.

Tip: Always match the valve’s pressure and temperature ratings to the system’s highest needs. Pick materials that resist the fluid and the environment.

Many people pick check valves by pipe size only. This causes trouble. Valves that are too big can shake and wear out fast. Valves that are too small cause high pressure loss and noise. Always size by flow rate, not just pipe size. Use the valve’s flow rating (Cv) to match the system. Protect valves from dirt with filters. Line up valves carefully to stop leaks and uneven wear.

Common sizing mistakes:

Picking by pipe size, not flow.

Not checking cracking pressure.

Forgetting to check flow direction.

Using the wrong gasket size.

Tightening bolts too much or too little.

Wrong pressure ratings can make valves fail. If the rating is too high, the valve may not open. If it is too low, the valve may not close or could break. This can cause leaks, pump damage, or system failure. Always check the system’s highest pressure and pick a valve that can handle it. Check valves often for signs of wear or damage.

Note: Correct sizing and pressure ratings keep systems safe and working longer. Never skip post-installation checks and pressure tests.

The wafer check valve vs flanged check valve comparison makes the differences easy to see. Wafer check valves are good for small spaces and cost less money. Flanged check valves work better with high pressure and are easier to fix. Picking the right valve for each job helps keep everything safe and working well.

Quick Checklist:

Look at how much space you have

Think about how much pressure you need

See how easy it is to fix the valve

Check which one costs less

Talk to experts if the job is hard

If you are not sure, valve specialists can help you avoid expensive problems.

Wafer check valves are smaller and lighter. Flanged check valves are stronger and last longer. Each one works best for different jobs in a pipeline.

Wafer check valves work best with medium pressure. For very high pressure, flanged check valves are safer and last longer.

Flanged check valves need more space and careful lining up. They take more time to put in than wafer check valves. Their strong fit makes them good for tough jobs.

Wafer check valves with spring discs close fast. This helps stop water hammer better than most flanged check valves.

Flanged check valves work better with dirty or thick fluids. Their strong build and bigger openings help stop clogs and damage.

Engineers should check wafer check valves every six to twelve months. Flanged check valves can go longer between checks but are harder to fix.

Yes. Wafer check valves go between flanges. Workers can take them out and put in new ones without cutting the pipe.

Wafer check valves are best for tight spaces. Their thin shape lets them fit where bigger valves cannot.